Boom Supersonic has announced Symphony, a new propulsion system designed and optimized for its Overture supersonic airliner. Boom also announced that it will be teaming with three industry leaders to develop Symphony including Florida Turbine Technologies (FTT) for engine design, GE Additive for additive technology design consulting, and StandardAero for maintenance.

“Developing a supersonic engine specifically for Overture offers by far the best value proposition for our customers,” said Blake Scholl, Founder and CEO of Boom Supersonic. “Through the Symphony program, we can provide our customers with an economically and environmentally sustainable supersonic airplane—a combination unattainable with the current constraints of derivative engines and industry norms.”

Symphony will be a bespoke design leveraging proven technologies and materials to achieve optimal supersonic performance and efficiency. Overture’s new propulsion system will operate at net zero carbon and meet Chapter 14 noise levels. When compared to derivative approaches, Symphony is expected to deliver a 25% increase in time on wing and significantly lower engine maintenance costs, reducing overall airplane operating costs for airline customers by 10%.

“United and Boom share a passion for making the world dramatically more accessible through sustainable supersonic travel,” said Mike Leskinen, President, United Airlines Ventures. “The team at Boom understands what we need to create a compelling experience for our passengers, and we are looking forward to a United supersonic fleet powered by Symphony.”

Symphony Collaboration

Boom has selected Florida Turbine Technologies, a business unit of Kratos Defense & Security Solutions, Inc., as its engine design team. FTT has leading supersonic engine design expertise, including key engineers among the team responsible for the design of the F-119 and F-135 supersonic engines that power the F-22 and F-35.

“The team at FTT has a decades-long history of developing innovative, high-performance propulsion solutions,” said Stacey Rock, President of Florida Turbine Technologies. “We are proud to team with Boom and its Symphony partners and look forward to developing the first bespoke engine for sustainable, economical supersonic flight.”

Boom also announced that GE Additive will collaborate on the Symphony program. Symphony will benefit from GE Additive’s proven track record of designing additively manufactured engine components—enabling more streamlined development, reduced weight, and improved fuel efficiency.

“We are excited to support Overture and Symphony,” said Chris Schuppe, General Manager Engineering and Technology at GE Additive. “GE Additive will bring industry-leading capabilities to Symphony, providing additive manufacturing design consulting and technology, while looking for additional areas to potentially collaborate.”

Additionally, StandardAero, one of the aerospace industry’s largest independent maintenance, repair, and overhaul (MRO) providers, will ensure that Symphony is designed for maintainability. Boom’s collaboration with StandardAero aims to deliver reliable and economical operations, and provision of maintenance services for the life of the aircraft.

Boom will also benefit from StandardAero’s experience as an assembler of supersonic engines. “We are excited to team with Boom as its strategic engine MRO partner and for the opportunity to contribute to the company’s bright future, ensuring its aircraft will receive the industry’s finest engine MRO services,” said Russell Ford, Chairman and CEO of StandardAero. “Our current qualifications, capabilities and experience assembling and servicing supersonic military jet engines makes us the intelligent solution for future commercial, supersonic engine MRO applications.”

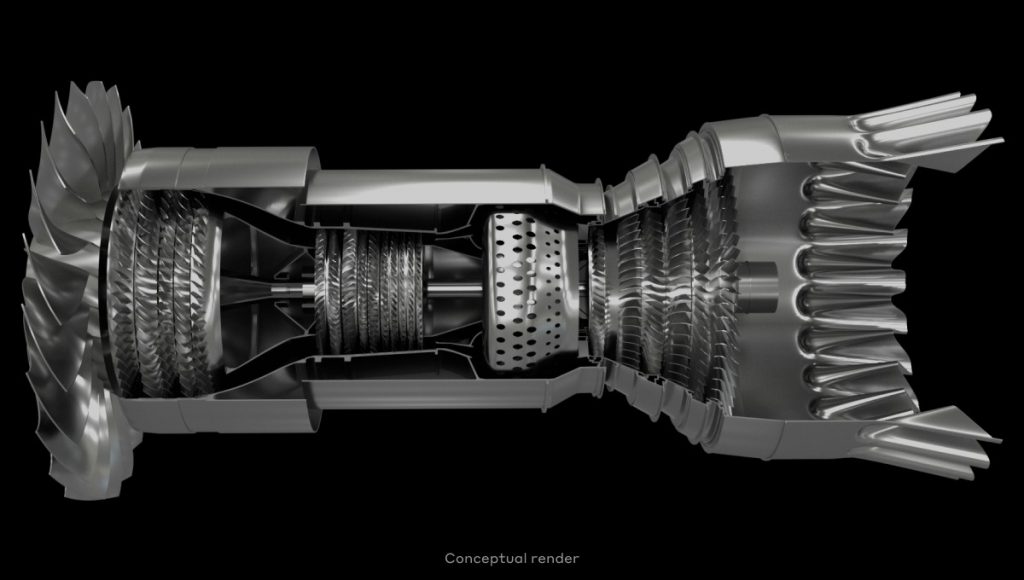

Symphony Technical Overview

Symphony will be a medium-bypass turbofan engine with the same basic engine architecture that currently powers all modern commercial aircraft. Unlike subsonic turbofans, this new propulsion system will include a Boom-designed axisymmetric supersonic intake, a variable-geometry low-noise exhaust nozzle, and a passively cooled high-pressure turbine.

Engine design features to include:

- Architecture: twin-spool, medium-bypass turbofan engine, no afterburner

- Thrust: 35,000lbs at takeoff

- Fuel: optimized for 100% Sustainable Aviation Fuel

- Single-stage fan designed for quiet operation

- Passively cooled high-pressure turbine

- Additive manufacturing for low weight, low part count, and reduced assembly costs

- Certification: compliant with FAA and EASA Part 33 requirements

Overture Program Schedule

With Symphony design already underway, Overture is on track to achieve type certification in 2029. Production is set to commence in 2024 at Overture’s Superfactory in Greensboro, NC, with rollout in 2026 and first flight in 2027.