How Improving Safety with Digitization Unlocks the Hidden Value of Airports

Photo above – Photo – Operation Iraqi Freedom night mission launch at sunset.

By Grant Bishop, CEO, Silent Falcon; Former USAF Squadron Commander F-16 “Wild Weasel” pilot

“If you think your airport doesn’t have a pavement problem, go touch the propeller blade of a locally based aircraft—you’ll feel the story your pavement is telling.”

From Combat Airfields to Community Airports

During combat operations in the Middle East, my squadron flew eight- to ten-hour missions every day. Our airfields were under constant strain from heat, fuel, sand, and heavy loads—yet we had to maintain 100 percent mission coverage, 24 hours a day.

To make that possible, we’d taxi eight F-16s to the runway to ensure four could get airborne. The other four filled in if needed or waited to launch in the next wave. While they waited another four ship would taxi early to back them up. It was a rolling cycle of readiness designed to overcome the high risk of FOD, debris, and surface damage that threatened every sortie.

That experience taught me a simple truth: the surface beneath the aircraft is as critical as the sky above it. And today, that same truth applies to America’s airports.

When the Chain of Safety Breaks

In 2024, Hawaiʻi’s Kona International Airport was shut down for two weeks after cracks spread across its only runway, forcing emergency repairs and repeated closures. A few months later, a Cessna Citation at Santa Fe Regional Airport struck a pothole on takeoff, damaging its landing gear and prompting a safety investigation and lawsuit.

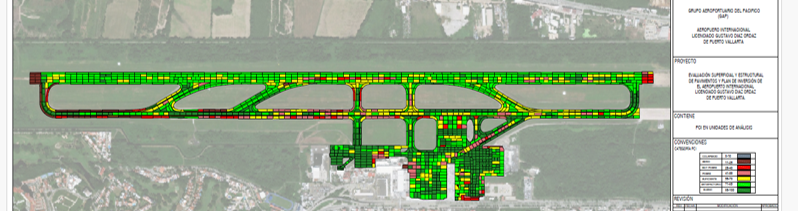

These events didn’t happen overnight—in many cases faulty partial inspections called 95% confidence inspections are performed. These DO NOT meet FAA requirements for Safety or Grants. Only detailed 100% total sampling inspections meet FAA requirements. How does this happen? Providers will boast they perform an ASTM D5340 PCI inspection. But there are two types…one samples and is unacceptable and the other is total sampling as spelled out in paragraph 7.5.1. It meets safety, maintenance and repair needs and AIP Grant requirements. Which one does your airport have? Ask for a Sample Unit Map from your provider. There is a legend that shows which sample units were inspected and which ones were not. Each fake inspection is a link towards an accident. Stop doing outdated inspection practices that end in operational and economic loss.

The Hidden Aerodynamics of a Rough Ramp

If you think your airport doesn’t have a pavement problem, go out to the ramp and feel a locally based aircraft’s propeller blade. If it’s rough instead of glass-smooth, that roughness probably came from your pavement.

When a propeller or jet engine operates close to the ground, it creates a small venturi—a kind of inverted tornado that pulls loose debris into the airflow. That debris sandblasts propeller blades and engines and signals early pavement failure. You can feel your airfield’s health in the smoothness—or roughness—of that blade.

Break the Chain: Inspect → Repair → Review

When you’re flying combat missions, you survive by breaking the chain before it breaks you. The same applies to runways. Every failure starts small, hides in the cracks, and grows in the silence between inspections.

1️⃣ INSPECT — 100% with AI based solutions–NOT partial inspections with measuring wheels.

Do 100% detailed inspections because they tell the whole story and the FAA approved MOS allows sUAS with AI to do ASTM D5340 PCI—and 100% is required under FAA AC 150/5380-7B and FAA Order 5190.6. See picture below of ASTM D5340 7.5.1 “Total Sampling” Note: Every 5000 square foot sample unit has a PCI rating.

If you’re only inspecting 10% of your pavement, you’re gambling with the other 90%—and putting your airport at risk for both safety and litigation.

Inspect everything. Know everything. That’s compliance—and survival.

AI will make your airport safer, better performing and lower Maintenance & Repair costs. Why would anyone jeopardize the lives of the flying public by using anything less?

2️⃣ REPAIR — Early. Surgical. Continuous.

Don’t wait three years to fix pavement. Frequent inspections let airports catch distresses early—crack seal, patch, micro-mill—before they become rebuilds.

FAA AC 150/5380-7B highlights that early, targeted repairs can cut long-term costs by 50–80%. Stop buying more sweepers to chase FOD; eliminate the source with fast, smart repairs.

The best maintenance is being preventative.

3️⃣ REVIEW — Close the loop or repeat the mistake.

After every repair, confirm the outcome. FAA Order 5190.6B makes follow-up inspections part of compliance.

Document what was fixed, record before-and-after PCI scores, and update maintenance histories.

The point isn’t just to fix—it’s to make better and not repeat mistakes.

⚡ Why Annual, Not Every Three Years?

Waiting three years between detailed inspections used to make sense—when it required clipboards, cones, and a measuring wheel.

Not anymore.

With FAA-approved Modifications of Standards (MOS) under AC 150/5380-7B, airports can perform sUAS-based PCI inspections safely, quickly, and at low cost.

No excuses. Inspect annually, repair immediately, review relentlessly.

That’s how you break the chain—before it breaks you.

Digitize Once. Use Forever.

Traditional inspections provide snapshots; digital twins tell the whole story. A single high-resolution data capture can support every requirement—from PCI and FOD to drainage, lighting, and ADA compliance.

By digitizing once and re-slicing the data for multiple reports, airports eliminate redundancy and meet FAA requirements faster, cheaper, and more accurately. The same data also helps plan smarter budgets and defend FAA grant compliance during audits. The data then become predictive as it is fused with operational information to help prevent accidents.

Beyond Safety: Monetizing Digitization

Digitizing airfields doesn’t just prevent failures—it builds value. Once an airport becomes a digital twin, every layer of information—pavement, lighting, markings, operations—connects directly to its users.

That data forms a personal link to the airport’s ecosystem: who’s flying, why, and how the airport supports their movement. This insight drives smarter business decisions, optimized hangar use, and targeted growth strategies.

It also unlocks the next step in urban air mobility (UAM)—using existing infrastructure and assets to enable short-hop connectivity across cities. The demand for UAM is now. There is an airport within 20 miles of 96% of the US population—UAM today is airport-to-airport then uber. That is the step we are at now and Silent Falcon is helping airports leverage this with data. Stop waiting for futuristic aircraft–use data to make the connections viable, safe and monetized.

Digitization turns airports from static infrastructure into intelligent mobility platforms—improving safety, driving revenue, and shaping the future of aviation one dataset at a time.

About the Author

Grant Bishop is the CEO of Silent Falcon, a specialized AI analytics company. A former commander of the U.S. Air Force’s 4th Fighter Squadron, NATO IG and Evaluator pilot, he had deployed to the Arctic circle, middle east, Asia pacific and Europe flying F16, F15, Soviet SU 22 and winner of the Torchlight flying competition in the T-38 Talon. 6 x Patent holder for aviation technologies that improve safety. He has led both military and commercial global aviation and technology teams for more than two decades. His FAA-approved digital-twin methodology for pavement analysis is deployed across military and civilian airfields worldwide.